AUGURY PEDALS

"The intersection of high performance engineering and industrial design"

From its inception, the primary goal of this project was to differentiate the Augury Pedals from everything else on the market. We aimed to develop a product that was innovative not only in functionality and engineering but also in the aesthetic language typically found in simulation hardware.

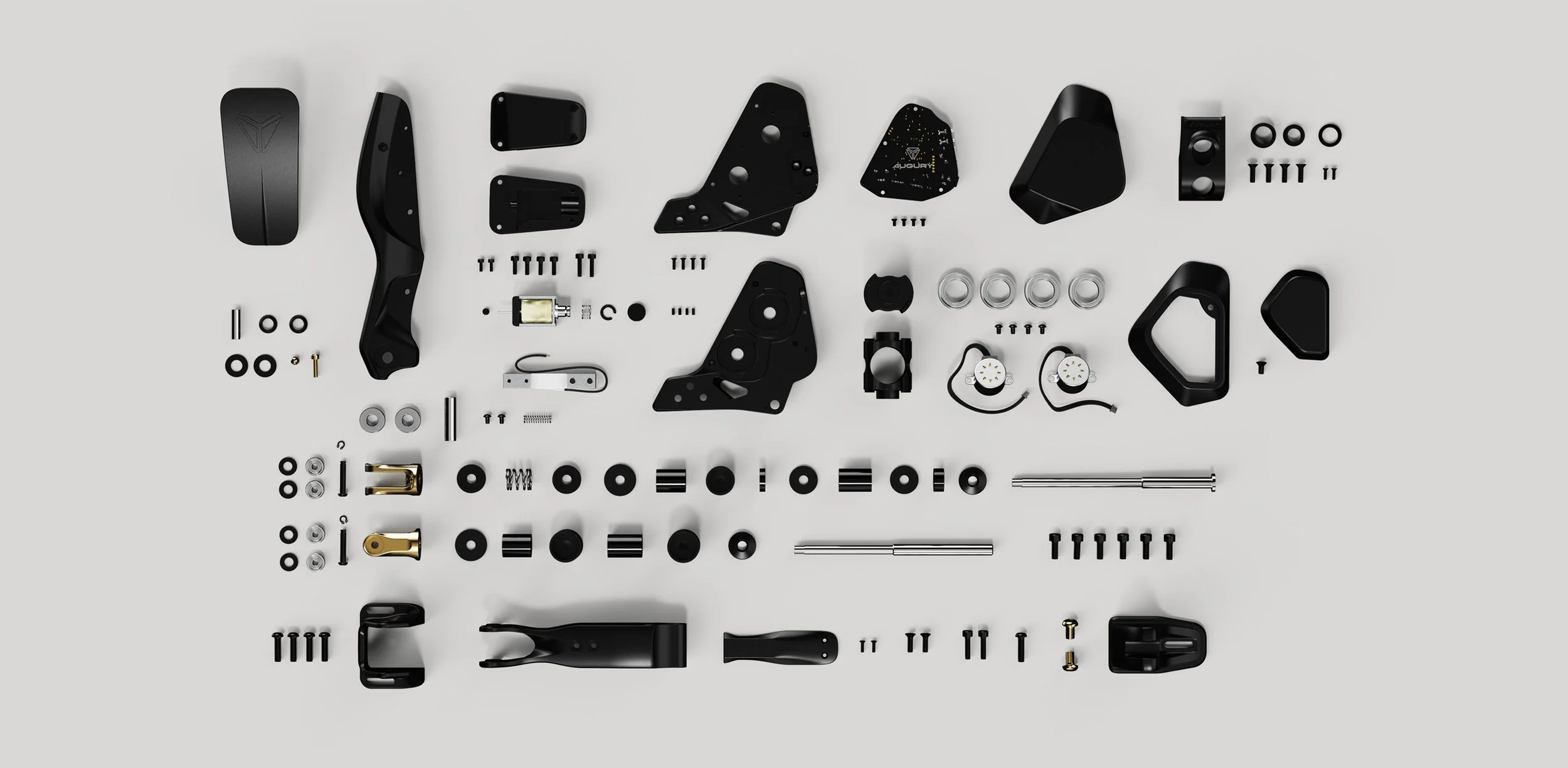

Working alongside the engineering team at Augury Simulations, we underwent a rigorous two year development process. After designing more than eighty custom parts and conducting extensive prototyping and testing, we achieved the AP-121. This set of simulation pedals offers meticulous aesthetics combined with technical features previously unseen in the industry.

The synergy of design and technical engineering

PROJECT DETAILS

Images: Carlos Jiménez

Work: Product design / Industrial design

Collaboration: Augury Team, Ruben Montaner

Meticulous focus on realism and detail

While developing the AP-121, our priority was to capture the most realistic driving sensations possible. We believed that aesthetics should be as vital as functionality. Every single component was treated as an individual design project, ensuring that the assembly presented interesting details and a clean silhouette from every possible angle.

User centric design and intuitive interaction

We integrated golden accents to reinforce the premium nature of the product. However, these details serve a functional purpose beyond luxury; they act as visual cues to indicate the specific parts the user interacts with. This intuitive system allows drivers to identify which screws and components are meant for adjustment, facilitating a seamless customization of the pedal set to their specific driving style.

Integrated electronics and seamless ergonomics

The Augury Pedals 121 were designed to offer an uncompromising driving experience, which includes the tactile feel and the precision of the parameters. A key design achievement was the total integration of the electronics. We ensured there are no visible cables, protecting all electronic components and sensors within the structure to guarantee a long life cycle and a clean, professional appearance.

Each pedal is a complex assembly of approximately forty meticulously designed parts, progressing from initial sketches to final three dimensional modeling. Produced in high quality anodized aluminum, the structure is complemented by carefully selected hardware, including bearings, springs, elastomers, and engines to ensure the most responsive and authentic feedback for the driver.

Sophisticated assembly with forty custom designed components

Product development and industrial prototyping

The Augury Simulations team dedicated over two years to the development of the AP-121. The journey from initial concepts and sketches to the final industrial result involved countless iterations, conceptual proposals, and high fidelity prototypes. This exhaustive process ensured that the final product successfully bridged the gap between complex engineering and a refined tech product aesthetic.